Updated 3/12/2024

If you’re familiar with abrasive materials and their applications, you understand the importance of selecting the right materials. Flap discs are no exception. Choosing the best one is essential to ensure your project’s success. Manufacturers are creating new abrasive advancements, and the global abrasives market is set to grow to $64.81 billion by 2029.

With more options available than ever, understanding the basics of flap discs and their materials, shapes and applications is essential to make an informed decision.

The Basics of Flap Discs

Flap discs are abrasive materials made from multiple overlapping flaps. While initially intended for right-angle grinder applications, they are versatile for many applications as they allow grinders to grind and finish in one step, lowering costs and saving time. They provide a similar experience to grinding wheels but are more user-friendly and controllable, reducing the risk of damaging the workpiece.

The Advantages of Flap Discs

Quality and efficiency are essential in many contracting applications. The right tools are crucial to achieve these objectives. Some of the many benefits of flap discs include:

- Excellent versatility: Flap discs allow you to grind, bend and finish with a single tool. They are ideal for applications from woodworking to concrete grinding or finishing.

- Improved maneuverability: A flap disc is a lightweight and easy-to-use solution, allowing grinders to complete tasks faster and more accurately.

- Reduced noise and vibration: Worker safety and comfort are paramount in environments requiring abrasive materials. Abrasive flap discs are quieter and vibrate less, making them safer and more comfortable for your team.

- Extended operating life: Flap discs require less change over time and remain functional after the flaps wear, which means a longer operating life. This durability results in long-term cost savings.

The right type of flap disc can transform your operations, providing a quality finish with minimal effort and keeping your operation profitable.

How to Choose the Right Flap Disc

The flap disc type you choose can affect your project outcomes. Matching it to your work materials is critical to get the desired finish. Understanding the types of flap discs and their uses is the first step to aligning your tools to your project. Let’s start by looking at some flat disc shapes and materials.

Choose the Right Flap Disc Shape

Flap discs are most commonly used with right-angle grinders, and different disc shapes offer various performance features. The most common flap disc shapes include:

- Type 29 conical flap: Conical flap discs have angled flaps to use for both edge and contoured work. They’re a straightforward choice, particularly when you need to quickly remove a lot of material, as they offer a larger surface area for stock removal.

- Type 27 flat flap: A flat flap disc is often the simplest finishing option. As the name suggests, you can only use them on flat surfaces, but they make easy work of blending and smooth finishing. These discs have flaps that adhere to the support plate to provide stability during operation.

Specialty disc shapes and sizes also exist for unique projects, including:

- Trimmable discs: These discs have a trimmable backing, so you can increase or adjust the flap overhang to streamline working on inaccessible areas.

- Angled discs: These options have curved flaps for enhanced control and multiple grinding angles.

- Aluminum-backed discs: A permanent robust aluminum backing supports operators throughout challenging applications.

- Mini discs: These discs are smaller than the standard options, perfect for working in impractical areas.

Find the Appropriate Flap Disc Material

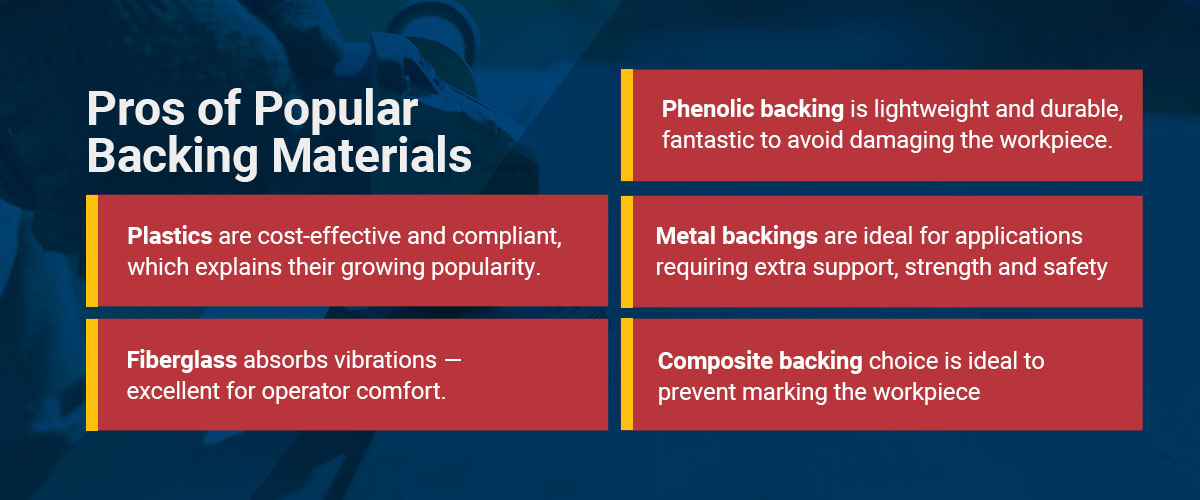

Abrasive flap discs come in various backing plate materials, each with pros and cons depending on your application.

The most popular backing plate materials include:

- Plastic: Backing materials are available in a range of plastics, although nylon is the most common. You can trim these backings to extend flap use, particularly during mixing and finishing. Plastics are cost-effective and compliant, which explains their growing popularity.

- Fiberglass: Fiberglass is one of the most sought-after backing material choices. It’s robust, lightweight and safe, forming a solid bond with the adhesive and eliminating the chance of contaminating the work surface. It also absorbs vibrations — excellent for operator comfort. As fiberglass also consists of layers, the more you add, the stronger the backing.

- Phenolic: Manufacturers create phenolic products by combining resin layers with composite fabric. This backing is lightweight and durable, fantastic to avoid damaging the workpiece.

- Metal: Metal backings are ideal for applications requiring extra support, strength and safety. However, they are more expensive, so using them only when necessary is perfect to maintain profitability.

- Composite: This backing choice is ideal to prevent marking the workpiece. It’s a trimmable backing, so you can adjust the disc’s dimensions, allowing access to hard-to-reach areas.

Once you’ve selected your backing, it’s time to consider the most effective abrasive grit material for your project. Some standard options include:

- Aluminum oxide: If you want to balance value and performance, aluminum oxide is a food choice. It’s durable, with a strong initial cut rate for fast stock removal. It’s ideal for all-purpose use but will dull over time.

- Ceramic alumina: Ceramic flap discs offer superior performance. As they grind, the grains microfracture to expose fresh, sharp edges consistently.

- Zirconia alumina: This self-sharpening option is perfect for aggressive stock removal and high-performance edge grinding. It provides a rapid cut and has excellent longevity when maintained correctly.

- Ceramic alumina and zirconia alumina blend: Combining the above options offers quick, accurate performance and enhanced disc longevity. Workers can achieve the same results with less effort.

Selecting the Appropriate Density

Like sandpaper grains, you can find flap disc grains in multiple sizes. They are numbered according to grain, with smaller numbers for coarser grit and larger numbers representing smoother options. Abrasives with lower grit numbers are an excellent starting point for stock removal and standard grinding. Higher numbers will give you a smooth finish.

Your choice depends on your project stage and desired result, but some basic guidelines include:

- The 36-40 range: This abrasive grit facilitates heavy-duty applications like stock removal.

- The 36-60 range: You can complete edge work like chamfering and beveling.

- The 40-60 range: You can use any abrasive grit in this range for weld grinding and blending.

- The 60 range: Abrasive grain in this range is perfect for deburring and deflashing.

- The 60-80 range: As the abrasive grit becomes finer, it’s more suitable for blending and rust removal applications.

- The 80-120 range: On the far end of the spectrum, abrasive grit in this range is optimal for refining applications.

How to Maximize Your Investment in Flap Discs

Even the best flap discs need replacing eventually. Balancing high performance with cost savings is essential if you work in a busy environment. In these cases, buying in bulk is often the most cost-effective and convenient option for businesses. Some of the benefits of purchasing bulk flap discs include:

- Long-term cost savings: Buying in bulk often gives you a lower per-unit price than purchasing individual items. Over time, paying less per unit adds up to considerable cost savings.

- Increased convenience: Instead of buying flap discs as needed, buying them all at once saves you time and ensures you have what you need without changing your schedule.

- Reduced environmental impact: When you buy bulk products, you save on packaging and fuel, reducing waste and carbon emissions for your business.

Buy Your Flap Discs in Bulk With National Abrasives, Inc.

Project quality is always a primary concern in construction, welding and many other applications. Recent advancements in flap disc technology elevate project quality and efficiency. You need a trustworthy flap disc provider to provide your clients with the best.

As a family-owned business for over 20 years, National Abrasives, Inc. has made our customers our priority. Our extensive range of flap discs, tools, accessories and supplies will give you the confidence to take on any project. Browse our flap discs today to find the perfect match for your next project. Alternatively, contact our experienced team to help you find the ideal flap disc today.

Learn More About Abrasives & Flap Discs

- How to Use a Finishing Sander

- How to Sand & Refinish Hardwood Floors

- Sanders & Abrasives for Grinding Aluminum

- Flap Wheel & Disc Products

*Updated: February 20, 2020